How to Maximize and Preserve the Value of Your Investment – Part 5

Maintenance, Repairs and Capital Replacement Plans for Industrial Buildings – Asphalt Paving

If you are an investor that owns and manages an industrial building or a portfolio of industrial buildings, then you will know that how you deal with the regular ongoing building maintenance, repairs and replacements of capital items can make a huge difference to your bottom line, as well as your tenant’s satisfaction.

About a month ago, we introduced our series on Maximizing and Preserving the Value of Your Investment, where we talked about producing a “Maintenance, Repairs, and Capital Replacement Plan” to ensure that you, as an owner and investor – can insulate yourself from large, sudden capital expenditures, as well as maintaining the integrity of your property.

Then we followed up with an overview of structuring leases to help recover expenses from your tenants, and how you may utilize a sink fund to prepare for the eventual repairs; thereby bulletproofing your investment and significantly reducing your risk as an investor and landlord.

We also spoke about Industrial Roofing Systems with Elite Roofing Contractors to understand more about maintaining and replacing that crucial building component.

Finally, we spoke with Richard Weldon of CDW Engineering about Heating and Air Conditioning Systems in industrial buildings.

In this week’s issue, we are covering Paving… We conducted thorough research on the topic and added over twenty-eight years of personal experience and observations… So, let’s understand more about maintaining, repairing and replacing asphalt and paving… and how you can do so to maximize the returns on your investments.

Ensuring that asphalt is performing properly is one of the crucial elements for any occupant of an industrial building. Ongoing regular maintenance will prevent a crisis in the future, and at the same time, extend its useful life.

So what should you do? How can you avoid any potential issues? And how can you make the best decision when the time comes for capital replacements?

Knowledge is power!

So let’s talk about Pavement… and define the components and terminology so we can have an accurate dialogue and discussion.

Pavement Design, Maintenance, and Replacement

The structural design of a pavement section is determined by assessing different combinations of the pavement surface, it’s base and sub-base layers, and selecting the optimum design that meets the specific project requirements.

Pavement consists of all structural elements or layers, including the shoulders, above the sub-grade. Although sub-grade is not part of the pavement structure, its characteristics, such as strength or load carrying capacity and drainage, are implicitly included.

Pavement may be flexible (asphaltic concrete), rigid (Hydraulic Cement Concrete), or a composite that is a combination of flexible and rigid pavements, such as an asphaltic concrete surface on a Hydraulic (Portland) Cement Concrete (HCC or PCC) base.

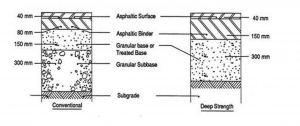

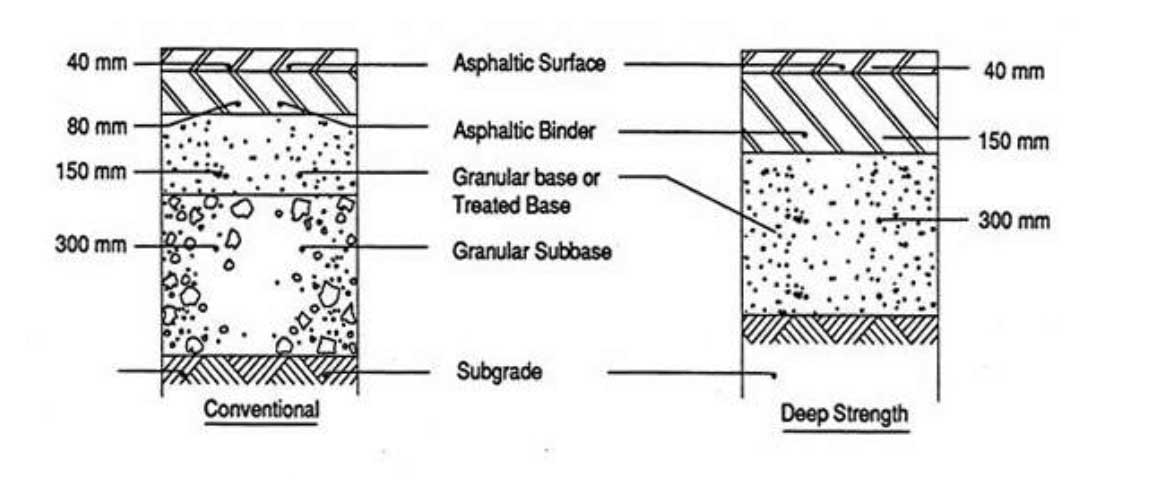

Typical Cross Section

HOT MIX ASPHALT (HMA)

Asphaltic concrete pavement – also known as hot mix asphalt (HMA) concrete pavement – is the most prevalent pavement type in Ontario. Flexible pavements can be separated into a variety of subtypes as indicated below:

- Conventional – less than 150 mm of asphaltic concrete on a granular base and sub base,

- Deep strength – 150 mm or more of asphaltic concrete on a granular base,

- Perpetual design – 200 mm or more of asphaltic concrete with or without the rich bottom mix (RBM) layer on a granular base, or

- Semi-rigid – HMA placed over cementitious stabilized materials.

Conventional flexible pavement is the most common pavement in most regions in Ontario and consists of an asphaltic concrete surface layer with underlying layers of asphalt concrete binder or leveling course layer, a granular base, and granular sub-base. The base and subbase layers are sometimes stabilized or bound.

Pavements with an asphaltic concrete thickness of 150 mm or more, and that are founded on a minimum 150 mm thick granular base are known as “deep strength”.

DESIGN FACTORS TO BE CONSIDERED

- Pavement Service Life or Pavement Performance Period – The time period, in years, between new construction of pavement and its first major rehabilitation, e.g. overlay or resurfacing, when performance has become inadequate.

- Traffic Loading – This is given in terms of AADT and the percentage of trucks. More rigorous pavement design procedures use cumulative standard 80 kN (8.2 tonnes) equivalent single axle loads (ESAL).

- Environmental Conditions – Design must account for temperature induced stresses, moisture and frost penetration.

- Sub-grade Soil – For simplicity, pavement design methods classify sub-grade soils into categories based on frost susceptibility and strength.

- Drainage – Good granular base and surface drainage are essential in order to maintain an adequate bearing capacity and to reduce the effects of freeze-thaw cycles.

- Minimum HMA Thickness

- Performance of Similar Pavements – A history of successes and failures between similar pavements in a given area is an important guide to developing an appropriate pavement design.

- Constraints and Physical Restrictions – Appropriate adjustments for local conditions are required, and are generally detailed in the pavement design report.

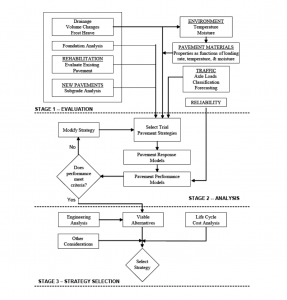

MECHANISTIC-EMPIRICAL PAVEMENT DESIGN GUIDE

The mechanistic-empirical design focuses on pavement performance expressed in terms of individual distresses (such as roughness, rutting, transverse cracking, faulting, and punch-outs) and takes into consideration all of the design features and conditions that directly affect pavement performance, such as materials, climate, traffic loads, and construction procedures.

The EPDG design approach consists of three major stages… Evaluation, Analysis, and Strategy Selection…

EPDG Paving Design Stages

The design process for new and rehabilitated pavement structures should consider the following:

- Foundation/sub-grade

- Existing pavement condition

- Paving materials

- Construction factors

- Environmental factors (temperature and moisture)

- Traffic Loadings

- Sub-drainage

- Shoulder design

- Rehabilitation treatments and strategies

- New pavement and rehabilitation options

- Pavement performance (key distress and smoothness)

- Design reliability

- Life cycle costs

DRAINAGE AND CONSTRUCTION CONSIDERATIONS

In preparation for paved areas, any remaining topsoil, organic, and deleterious materials should be removed to expose the undisturbed inorganic subsoils, or the controlled or engineered fill material.

Prior to placing any granular material, the exposed sub-grade should be free of any frost susceptible materials and should be proofrolled in conjunction with an inspection by qualified geotechnical personnel. Remedial work should be carried out on any disturbed, softened, or poorly performing zones as directed by geotechnical personnel.

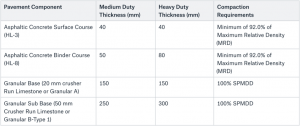

The granular sub-base and base materials should be uniformly compacted to 100 percent of its Standard Proctor Maximum Dry Density (SPMDD). Compaction of the granular materials and subgrade soils should be carried out at a moisture content that is within 2 percent of the optimum moisture content.

The asphaltic concrete materials should be compacted to a minimum of 92 percent of their Maximum Relative Densities (MRD), as measured in the field using a nuclear density gauge.

Subsurface drainage is required to preserve the integrity of the pavement structure. The sub-grade should be carefully proofrolled to a smooth surface and sloped towards the catch basins to prevent ponding or entrapment of water in the sub-base, which would lead to weakened sections and generally poor performance.

Recommended Pavement Design for a typical industrial development for new construction:

The Granular Base shall meet the Ontario Provincial Standards Specifications (OPSS) gradation requirements for Granular A. The Granular Sub-Base shall meet the OPSS gradation requirements for Granular B Type-1. The Granular Base and Sub-Base should be compacted to at least 100% of their SPMDD.

The asphaltic concrete courses should be hot-mixed and laid in accordance with current OPSS specifications and compacted to a minimum of 92% of Maximum Relative Density (MRD).

All of this is based on the assumption that weather conditions are ideal, failing which, additional imported sub-base material may be necessary. The long term performance of the pavement is highly dependent on the subgrade support conditions.

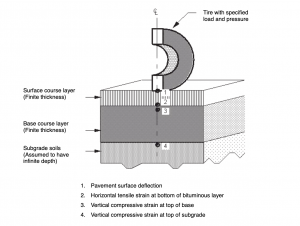

Pavement Design Critical Analysis Locations

A variety of structural distresses are considered in flexible pavement design and analysis, like:

- Bottom-up fatigue (or alligator) cracking,

- Surface-down fatigue (or longitudinal) cracking,

- Fatigue in chemically stabilized layers (only considered in semi-rigid pavements),

- Permanent deformation (or rutting), and

- Thermal cracking.

Cracked Asphalt Paved Surface

Such pavement surface distresses usually in the form of rutting, transverse cracking, fatigue cracking and distress associated with environmental impacts are nevertheless common flexible pavement problems in many municipalities across the province, including the City of Toronto. Fatigue cracking can often be attributed to insufficient HMA layer thickness for the projected traffic loading.

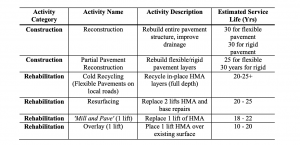

Asphalt Construction and Rehabilitation Estimated Service Life

Pavement Maintenance

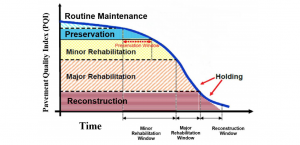

The key to long-term, cost-effective pavement performance is the use of appropriate rehabilitation, preservation, and routine maintenance options completed at the right time during the service life of the pavement.

Loss in Pavement Quality Index (PQI)

- Preservation – treatments designed to be proactive and applied while the pavement is still in good condition, to maintain a high level of service.

- Routine Maintenance – planned, reactive, and preventive work completed on a routine basis to address immediate problems.

- Holding – a short-term strategy that prolongs the life of the pavement at acceptable levels of functionality or safety until rehabilitation or reconstruction can be completed.

Furthermore, and to provide some clarity on the current cost in the Greater Toronto Area, below is a quote that we recently received on behalf of one of our clients to remove and replace asphalt:

Lastly, in order to ensure that such capital expenditure is recovered form the tenant and that it forms part of the additional rent, a similar clause might be used in the Lease Agreement:

“During the term of this Lease, and any extensions or renewals thereof, if any part of the parking area, driveways or trucking/shipping areas of the Leased Premises cannot be repaired and reasonably requires repaving, as determined by the Landlord acting reasonably, the reasonable costs incurred by the Landlord for such repaving, which shall be amortized on a straight-line basis with interest at Royal Bank prime rate plus two (2) percentage points over the period of fifteen (15) years shall form part of the additional rent.”

Obviously, there are so many ways to “skin the cat”, this is just an example that can be further modified on a case by case basis. Please consult your legal advisor for further clarification.

Conclusion:

Overall, it is important to fully understand the condition of the asphalt paving in your industrial buildings, their state of repair, their remaining useful life, and to have a plan in place for maintenance… This way you will avoid any surprises…

So, in order to maximize its life expectancy and ensure optimum operating efficiency, it is important to regularly conduct annual maintenance and repairs….. This investment of time and money will pay back dividends in the future and mitigate potential risks…

If you have any thoughts or questions on any of the topics we’ve covered over the past month regarding capital repairs or replacements, feel free to reach out.

Until next week…

Goran Brelih and his team have been servicing Investors and Occupiers of Industrial properties in Toronto Central and Toronto North markets for the past 25 years.

Goran Brelih is a Senior Vice President for Cushman & Wakefield ULC in the Greater Toronto Area.

Over the past 27 years, he has been involved in the lease or sale of approximately 25.7 million square feet of industrial space, valued in excess of $1.6 billion dollars while averaging between 40 and 50 transactions per year and achieving the highest level of sales, from the President’s Round Table to Top Ten in GTA and the National Top Ten.

Goran is currently serving as Immediate Past President of the SIOR ‐ Society of Industrial and Office Realtors, Central Canadian Chapter and on the Board of Directors of Muki Baum Accessibility Centre, a Toronto‐based NGO which provides support to children and adults with complex disabilities.

Specialties:

Industrial Real Estate Sales and Leasing, Investment Sales, Design-Build and Land Development

About Cushman & Wakefield ULC.

Cushman & Wakefield is a leading global real estate services firm that delivers exceptional value by putting ideas into action for real estate occupiers and owners. Cushman & Wakefield is among the largest real estate services firms with 48,000 employees in approximately 400 offices and 70 countries.

In 2017, the firm had revenue of $6.9 billion across core services of property, facilities and project management, leasing, capital markets, advisory, and other services. To learn more, visit www.cushmanwakefield.com or follow @CushWake on Twitter.

For more information on GTA Industrial Real Estate Market or to discuss how they can assist you with your real estate needs please contact Goran at 416-756-5456, email at goran.brelih@cushwake.com, or visit www.goranbrelih.com.